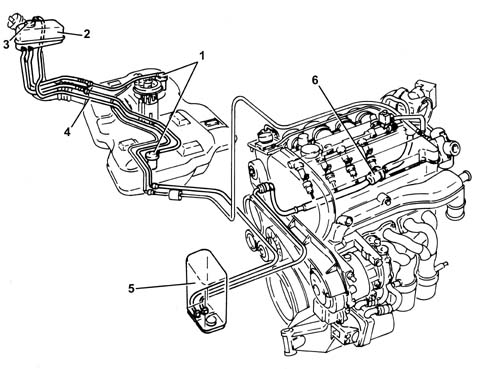

3232855 - 1080E evaporation control system

Operation

The vapours coming from the tank through the two multi-purpose valves (1) are sent to the separator (2).The vapours condensed in the separator fall back into the tank.Uncondensed vapours are sent through the multi-purpose valve (3) and the pipe (4) to the canister (5), where they are absorbed and stored by the activated charcoal.The vapours pass to the inlet box through the solenoid (6) controlled by the fuel injection control unit.

Multi-function valves

The multi-purpose valve has the following functions:

- pressurizing the tank

- ventilating the tank

- retention

- seal in the event of roll-over

| The multifunction valve can be removed from the separator and a Viton gasket ensures a perfect seal. |

Pressurizing the tank

The tank is maintained at a pressure of 30-45 mbar by means of a fluorosilicone rubber valve, which rests on a sealing edge.The valve is supported by a stainless steel plate and counteracted by a spring.When the pressure in the tank exceeds the specified value, it overcomes the resistance of the spring and the valve is able to rise, allowing vapours to flow to the canister.When the pressure returns to the correct limits, the valve closes again.Retention

Under particular driving conditions, a vacuum could be created in the tank because of:

- temperature changes

- fuel consumption.

Seal in the event of roll-over

The roll-over function prevents fuel from leaking from the tank if the vehicle overturns or is on a very steep slope.During normal driving of the vehicle (bends, acceleration, braking, etc.), the fuel is shaken up and may spill into the canister.The car's high roll-over sensitivity prevents this spillage.The roll-over closure angle is less than 33°.SAFETY AND VENTILATION VALVE

Operation

This valve is built into the fuel filler cap, and it carries out the following functions, depending on the pressure present in the tank:Excess pressure in the tankWhen pressure in the tank exceeds a specified level, it acts on the plate (2) and, overcoming the load of the spring (1), allows excess vapours to be discharged outside.Vacuum in the tankWhen excess vacuum is created in the tank due to fuel consumption, it overcomes the load of the spring (4) and moves the valve (3), allowing air to enter.

Canister

Mounted in the front right wheelarch, this consists of an activated-charcoal filter element which absorbs the fuel vapours coming from the separator.A hole in the canister allows air to be taken in and takes the form of a labyrinth to prevent water entry.The fuel vapour inlet and outlet pipes are heat welded to the canister and cannot therefore be dismantled.

Fuel vapour solenoid

This is fitted in the lower part of the air capacity chamber and is controlled by the injection control unit.The function of the solenoid is to allow fuel vapours stored in the engine intake canister through to the engine intake.If there is no supply, the solenoid is in the open position; when the ignition key is in the ON position, the solenoid closes, ready for operation.If energized, the electromagnet (1) attracts the shutter (2) which overcomes the load of the flat spring (3) and closes the hole (4), preventing the passage of fuel vapours.