3232853 - 1080B exhaust emission control system

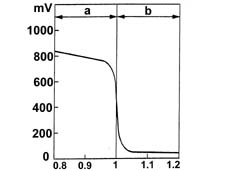

The electronic control unit identifies the

composition of the mixture (rich or lean) from the Lambda sensor output

voltage.It adjusts the quantity of fuel injected

to ensure the optimum composition of the mixture (l = 1) to create

the ideal conditions for the treatment of the exhaust gases in the

catalytic converter.If the mixture is too rich (lambda less

than 1), then the quantity of fuel should be reduced and, if the

mixture is too lean (lambda greater than 1), then the quantity of

fuel should be increased.

a, Rich mixture (lack of air)

b, Weak mixture (too much air)

Lambda probe

Of the 'planar' type, it is mounted on the

front section of the exhaust pipe, and it informs the control unit about

the combustion trend (stoichiometric ratio).

To obtain an optimum mixture, the quantity

of air drawn in by the engine is the same as the theoretical quantity

that would be needed to burn all the injected fuel.In this case the Lambda factor (?) the ratio

between the quantity of air drawn in and the theoretical quantity of

air (needed to burn all the injected fuel), is 1.Thus:

- Lambda = 1: ideal mixture;

- Lambda greater than 1: lean mixture;

- Lambda less than 1: rich mixture.

a, Rich mixture (lack of air)

b, Weak mixture (too much air)

The Lambda sensor, placed in contact with

the exhaust gases, generates an electrical signal whose voltage depends

on the concentration of oxygen present in the gases.This voltage undergoes a sudden variation

when the composition of the mixture moves away from the value ?

= 1.The heating of the Lambda sensor is managed

by the fuel injection control unit in relation to the exhaust gas temperature.This avoids thermal shocks on the ceramic

casing due to the contact with condensed water, present in the exhaust

gases when the engine is cold.The measuring cell and heater are built

into the 'planar' (stratified) ceramic element, with the advantage

of obtaining quick heating of the cell, thus permitting a closed

loop' check (? = 1) within 10 seconds of engine start-up.

1, Connecting cable

2, Protective sleeve

3, Planar sensor element

4, Ceramic tube casing

5, Probe seating

6, Ceramic seal

7, Protective tube

The operation of the Lambda sensor is based

on the principle of an oxygen concentration cell with solid electrolyte.The surfaces of the measuring cell are coated

with microporous layers of noble material.

1, Exhaust gases

2, Passage of reference air

3, Heater

4, Lambda sensor voltage

For operating checks

See Test 1080B Check operation of fuel vapour recovery solenoid

valve

.

Catalytic converter

The three-way catalytic converter

simultaneously reduces the three polluting gases present in the

exhaust gases:

- unburnt hydrocarbons (HC);

- carbon monoxide (CO);

- nitrogen oxides (NOx).

Two types of chemical reactions take

place in the converter:

- oxidation of the CO and HC, converted into carbon dioxide

(CO2 ) and water (H2 O)

- reduction of the NOx converted into nitrogen (N2 ).

The converter consists of a monolith, a

metal mesh support for damping impacts and vibrations and an outer stainless

steel housing resistant to high temperatures and atmospheric agents.The monolith consists of a honeycomb structure

comprising a ceramic material coated with a very thin layer of catalytically

active substances, platinum or rodium. These accelerate the chemical

decomposition of the harmful substances contained in the exhaust

gases which, passing through the core cells at temperatures of over

300°- 350° C, activate the catalyzers, thus starting the oxidoreduction

reactions. To optimize the efficiency and duration

of the catalyzer, a perforated plate metal cone improves the diffusion of

the exhaust gases in the cells of the ceramic core.

1, Ceramic monolith

2, Metal support

3, Outer casing

4, Perforated plate metal cone

| The noble metals contained in

the catalytic converter, because of the high temperature, are chemically attacked

if lead is present.For this reason the use of petrols containing

lead should be avoided, otherwise the converter will be quickly

and irreversibly damaged.Never use petrol containing lead,

not even in an emergency or for a very short time. |