3239548 - Introduction - REMOVING REFITTING

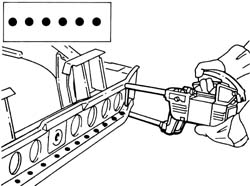

The graphic index and the description of the symbols appearing in the repair procedures are given below.SYMBOLS

.

PROCESSING SYMBOLS

The symbols are given below of the work tasks which are described in the repair procedures with an example of application. In the descriptions of the procedures, beside the progressive number of the steps of the procedure relating to welding tasks, there may be numbers in brackets which indicate the number of spot welds to be made or to be filled by MIG welding.Cut made by hack saw or pneumatic chisel