3232879 - 1060G pressure pump electric control

COMPONENT DESCRIPTION

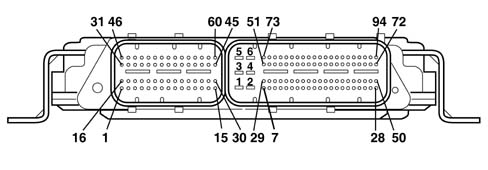

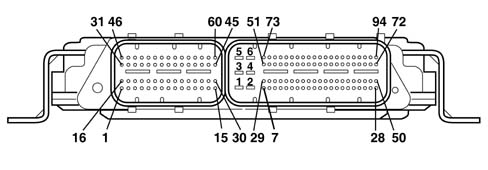

Injection control unit (EDC-15C Common Rail)

It is fitted to the right side of the engine

bay. The control unit is the 'flash EPROM' type, i.e. reprogrammable from

the outside without intervening on the hardware.The injection control unit integrates the

absolute pressure sensor.PIN-OUT

RPM SENSOR

Specifcations

It is fitted on the cylinder block/crankcase

and 'faces' the flywheel on the crankshaft.It is of the inductive type, i.e. it functions

by means of the variation in the magnetic field generated by the passage

of the teeth of the flywheel (60-2 teeth).The fuel injection control unit uses

the rpm sensor to:

- determine the rotation speed;

- determine the angle of the crankshaft.

Operation

The passage from full to empty, due to the

presence or absence of the tooth, causes a variation in the magnetic flow

which is sufficient to generate an induced alternating voltage,

resulting from the count of teeth located on a ring (or phonic wheel).The frequency and range of the voltage sent

to the electronic control unit provides it with the angular speed of

the crankshaft.

1 - Brass bush

2 - Permanent magnet

3 - Plastic sensor casing

4 - Coil winding

5 - Polar core

6 - Ring gear or flywheel

7 - Coaxial two-wire cable or electrical connection

The distance (gap) for obtaining correct

signals, between the end of the sensor and the flywheel, should

be between 0.8 and 1.5 mm.This gap is not adjustable, so if a value

outside the tolerance range is measured, check the condition of

the sensor and the flywheel.

1 - Maximum magnetic flow

2 - Minimum magnetic flow

3 - Induced alternating voltage trend

CAM ANGLE SENSOR

Specifcations

Hall effect; it is mounted on the cylinder

head and 'facing' the camshaft pulley.This pulley comprises a tooth which enables

the timing sensor to indicate the engine's timing position.The fuel injection control unit uses the

timing sensor's signal to find out the TDC at the end of compression.Operation

A semiconducting layer, through which current

passes, immersed in a perpendicular magnetic field (force lines perpendicular

to the current direction), generates at its ends a difference in

potential known as Hall voltage.If the intensity of the current remains

constant, the voltage generated only depends on the intensity of

the magnetic field; the intensity of the field simply has to vary

periodically to produce a modulated electrical signal, whose frequency

is proportional to the speed with which it changes magnetic field.

To obtain this change, a tooth on the inside of the pulley moves

close to the sensor.

1 - Earth

2 - Signal

3 - Supply

INTAKE AIR TEMPERATURE AND EXCESS PRESSURE SENSOR

Specifcations

The intake air temperature and excess pressure

sensor is a component which is designed to measure the pressure

and the temperature of the air inside the inlet manifold.It is fitted on the intake manifold

has the task of notifying the injection control unit to:

- regulate the pressure of the variable geometry turbine

in order to ensure optimum engine performance in all operating conditions.

- regulating injection duration.

1 - Earth

2 - Air temperature signal

3 - 5 Volt (from ECU)

4 - Supercharging pressure output signal

ENIGINE COOLANT TEMPERATURE SENSOR

Specifcations

It is fitted on the thermostatic cup and

measures the temperature of the coolant by means of an NTC thermistor which

has a negative resistance coefficient.One NTC thermistor sends the signal to the

injection control unit whilst the other one sends the signal to

the temperature gauge and warning light in the instrument panel.The sensor is based on semiconductor technology;

so if the sensor temperature increases as the water temperature

increases, the resistance decreases.As the variation in resistance is not linear,

for the same temperature increment, it is higher for low temperatures than

for high temperatures.AIR FLOW METER WITH AIR TEMPERATURE SENSOR INTEGRATED

Specifcations

The flow meter is located on the air inlet

duct and is of the 'hot film' type.

1 - Air temperature sensor output signal

2 - Maintenance current

3 - Negative

4 - 5V supply

5 - Flow meter output signal

The intake air temperature sensor is built

into the flow meter. | The air flow meter cannot be dismantled. |

Operation

The operating principle is based on a heated

diaphragm located in a measuring duct through which the intake air

entering the engine flows.The hot film diaphragm is kept at a constant

temperature (about 120° C above the incoming air temperature) by

the heating coils.The air mass passing through the measuring

duct tends to draw heat from the diaphragm, so to keep the latter at

a constant temperature, some current must flow through the resistor.This current is measured by a suitable Wheatstone

bridge.The current is therefore proportional to

the mass of flowing air. | The flow meter directly measures

the air mass (not volume), thus eliminating problems of temperature,

altitude, pressure, etc. |

Fuel temperature sensor

Specifications

It is built into the fuel heater and measures

the temperature of the coolant by means of an NTC thermistor which

has a negative resistance coefficient.The sensor is based on semiconductor technology;

so if the sensor temperature increases as the fuel temperature increases,

the resistance decreases.As the variation in resistance is not linear,

for the same temperature increment, it is higher for low temperatures than

for high temperatures.FUEL PRESSURE SENSOR

Specifcations

It is fitted at the end of the 'rail'

fuel distribution manifold and has the task of supplying the injection

control unit with a 'feedback' signal to:

- regulate the injection pressure

- regulating injection duration.

1 - Earth

2 - Output signal

3 - Supply

ACCELERATOR PEDAL POTENTIOMETER

Construction features

The sensor consists of a casing, secured

to the accelerator pedal mount, which contains a shaft, in an axial position,

connected to two potentiometers: one main one and one safety one.There is a coil spring on the shaft which

guarantees the correct resistance to the pressure whilst a second spring

ensures the return on release.Operation

The position of the accelerator pedal is

transformed into an electrical voltage signal and is sent to the

fuel injection control unit by the potentiometer connected to the

accelerator pedal.The accelerator pedal position signal is

processed together with the information relating to the rpm, to

obtain the fuel injection times and relevant pressure.