3232853 - 1080B exhaust emission control system

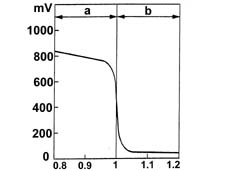

The electronic control unit identifies the composition of the mixture (rich or lean) from the Lambda sensor output voltage.It adjusts the quantity of fuel injected to ensure the optimum composition of the mixture (l = 1) to create the ideal conditions for the treatment of the exhaust gases in the catalytic converter.If the mixture is too rich (lambda less than 1), then the quantity of fuel should be reduced and, if the mixture is too lean (lambda greater than 1), then the quantity of fuel should be increased.

COMPONENT DESCRIPTION

CATALYTIC CONVERTOR

Specifcations

The oxidizing catalyzer is a post-treatment device for oxidizing the CO, HC and particle matter, transforming them into carbon dioxide (CO2) and water vapour (H2O).The catalytic converter consists of a ceramic, honeycomb structure monolith (1) with cells impregnated with platinum (2), which acts as a catalyst for the oxidation process.