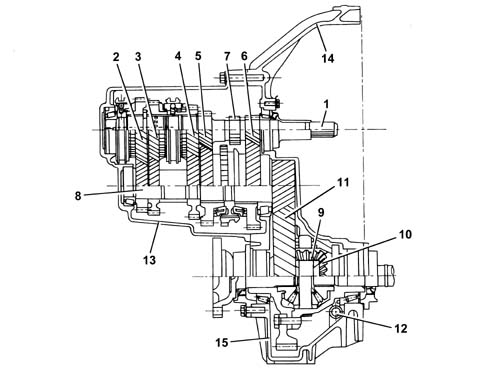

3239209 - Introduction - MANUAL GEARBOX AND DIFFERENTIAL

DESCRIPTION

Gearbox structure

The structure of the gearbox consists of:

- a gearbox casing with a "closed end" configuration with the rear cover eliminated. This contains and support the main and layshaft, the gear engagement selector forks and rods and the gear selector/engagement device.

- the bell housing which contains the clutch, the thrust bearing and the control device.

Main shaft

The main shaft consists of:

- 1st, Reverse and 2nd speed gears

- 3rd , 4th , 5th /6th speed gears, fitted on needle bearings with the synchronizers

The seal makes it possible to:

- reduce the wear of the synchronizers

- improve the matching of the gears

- reduce the noise from the bearings

- improve the manoeuvrability of the gearbox.

Layshaft

The layshaft consists of:

- 1st and 2nd speed gears, fitted on needle bearings with synchronizers

- 3rd , 4th and 5th /6th speed gears fitted on the shaft.

Gears

The gears are the following type:

- helical toothed for the forward speeds

- straight toothed for Reverse.

All the gears have been designed with "high cover factor" teeth, i.e. when one of the matching teeth is in contact, the next tooth has already started meshing which has the advantage of:

- reducing transmission irregularities

- reducing operating noise.

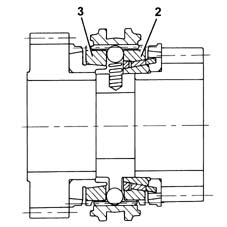

Synchronizers

The synchronizers for all the gears are brass, baulk ring "Borg-Warner" of the following type:

- triple cone (1) for 1st and2nd speeds

Multiple cone synchronizers make it possible to:

- distribute the lever engagement load over several cones

- facilitate the engagement of the gears.

Gear shift/selection system

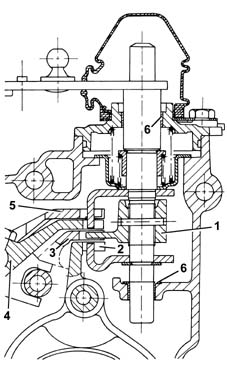

There are four selection levels for the gear selection/control system with the gear positioner fitted with a bearing.The system ensures that it is impossible to accidentally engage Reverse gear as it is on a separate level.Two bushes (6) with a Permaglide covering have been used to reduce friction at:

- the couplings between the gear selector/engagement control shaft and the gearbox casing

- the couplings for the selector fork rods and the gearbox casing.

The bushes make it possible to:

- achieve improved sliding

- ensure better gear engagement precision.

Differential

The differential consists of:

- a crown wheel and pinion reduction

- a differential housing made from two half casings which include the planet and satellite gears.

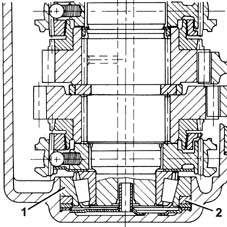

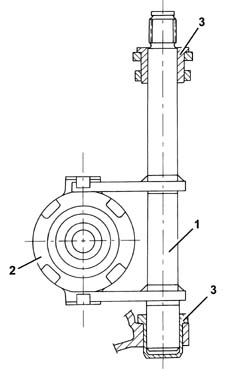

Clutch operation

The clutch control consists of:

- a fork bearing (1) fitted inside the clutch casing

- a thrust bearing (2) fitted on the main shaft

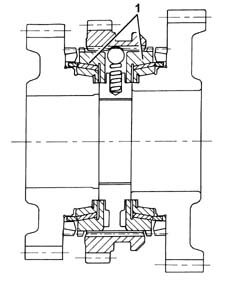

The fork bearing is supported by the Permaglide bushes (3) which make it possible to:

- reduce the force required to operate the clutch pedal

- eliminate the use of grease

- limit the wear of the coupling.

Lubrication

In addition to the "whipping effect", the gears are also lubricated by means of ducts inside the:

- clutch casing and gearbox casing

- 3rd and 4th speed control rod

- main shaft.

The improved lubrication of the ducts makes it possible to:

- improve the efficiency of the lubrication

- reduce the amount of oil used thanks to the lubrication aimed at the main couplings.