3239547 - Introduction - PANELS AND FRAME

REPAIRING THE VEHICLE

Vehicle identification data

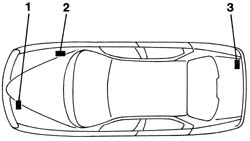

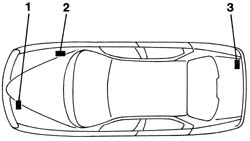

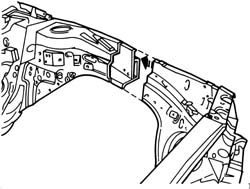

Location of plates on the vehicle

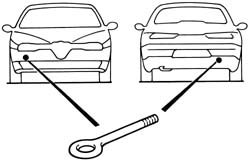

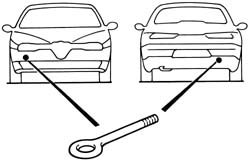

Towing points

Location of tow hook threaded sockets

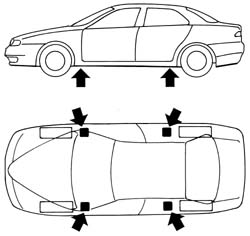

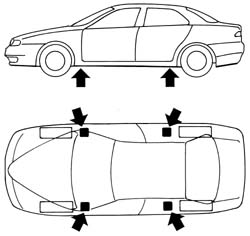

Vehicle lifting points

Position of vehicle lifting points

Vehicle repair operating cycles

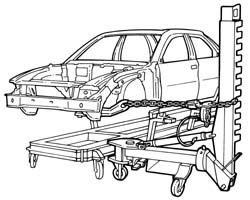

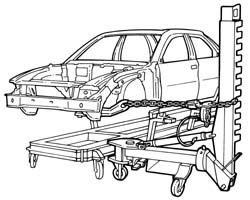

Pulling the bodyshell

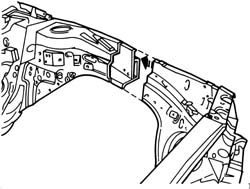

The bodyshell measurements are checked using templates, to be positioned at certain points, which are used to check the measurements against those given by the manufacturer for each model or, alternatively those given for the vehicle on the previous pages.

General repair instructions

Correct method for carrying out cutting operation

Hack-sawing machine

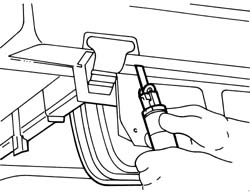

Example of the use of a hack-sawing machine

Oscillating circular saw

Example of an oscillating circular saw

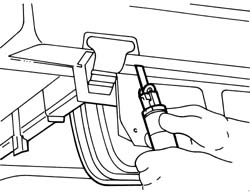

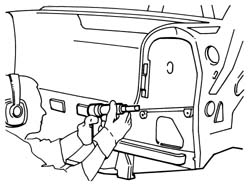

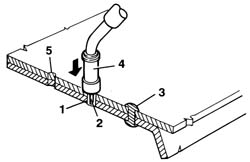

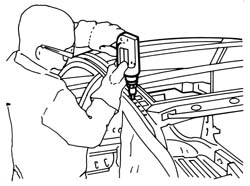

Power chisel

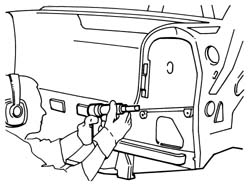

Example of the use of a power chisel

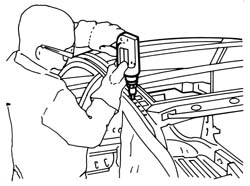

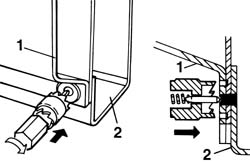

Electric drill

Example of the use of an electric drill

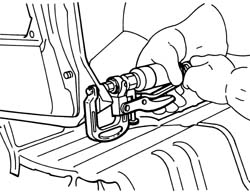

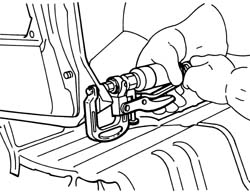

Milling cutter

Example of the use of a milling cutter

Welding replacement elements

Parts of the fuel system

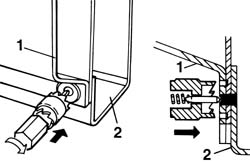

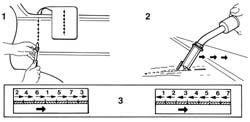

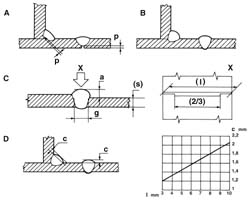

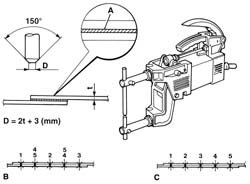

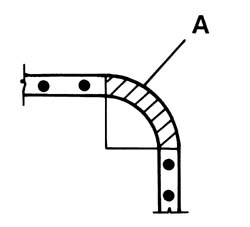

Spot welding

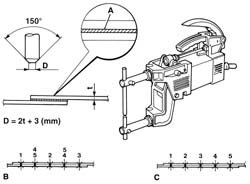

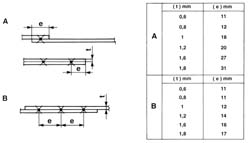

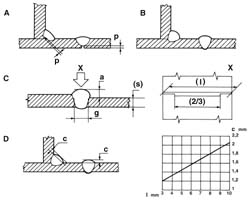

Spot welder, geometric characteristics of the electrode according to the thickness of the panel and the welding sequence.

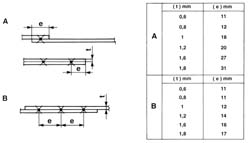

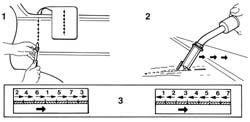

Operating methods

Carrying out a weld using inert gas (MIG) for joining two matched panels.

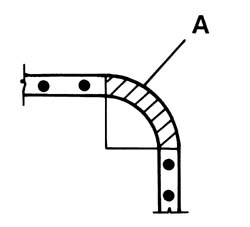

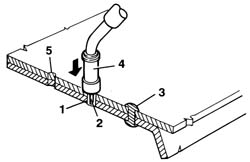

General instructions for exposed welding

Examples of welding

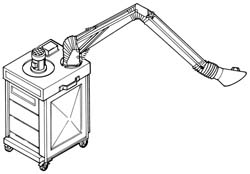

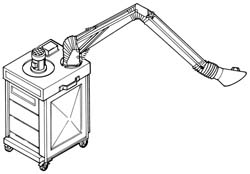

Air filtration and purification system

Example of a portable air filtration and penetration system

REPAIRING THE VEHICLE

PAINTING

Introduction

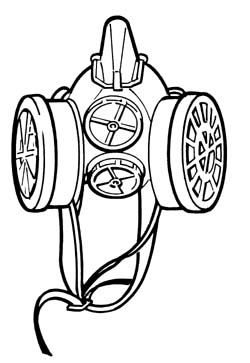

Filtration mask

Example of a filtration mask

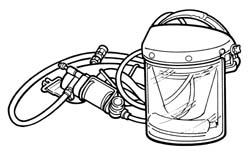

Pressurized mask

Example of a pressurized mask

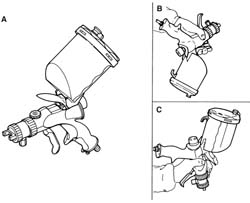

Spray guns

Using a spray gun

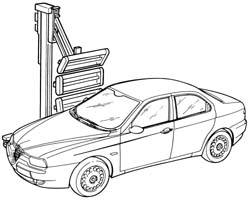

Portable infra-red lamps

Drying a retouched area using a portable infra-red lamp

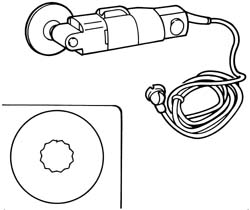

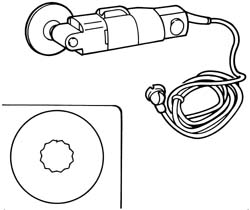

Polishers

Correct use of a polisher

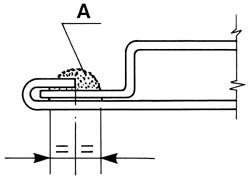

Renew the anti-corrosion/sound insulation/sealant treatments.

Equipment

Examples of application of sealant

REPAIRING THE VEHICLE

Vehicle identification data

Location of plates on the vehicle

Towing points

Location of tow hook threaded sockets

Vehicle lifting points

Position of vehicle lifting points

Vehicle repair operating cycles

Pulling the bodyshell

The bodyshell measurements are checked using templates, to be positioned at certain points, which are used to check the measurements against those given by the manufacturer for each model or, alternatively those given for the vehicle on the previous pages.

General repair instructions

Correct method for carrying out cutting operation

Hack-sawing machine

Example of the use of a hack-sawing machine

Oscillating circular saw

Example of an oscillating circular saw

Power chisel

Example of the use of a power chisel

Electric drill

Example of the use of an electric drill

Milling cutter

Example of the use of a milling cutter

Welding replacement elements

Parts of the fuel system

Spot welding

Spot welder, geometric characteristics of the electrode according to the thickness of the panel and the welding sequence.

Operating methods

Carrying out a weld using inert gas (MIG) for joining two matched panels.

General instructions for exposed welding

Examples of welding

Air filtration and purification system

Example of a portable air filtration and penetration system