2753579 - Introduction - PANELS AND FRAME

General safety warnings

The activities connected with

repairing the bodywork involve the use of equipment and tools in

addition to the handling of chemical products and substances for

which the supplier's instructions must be followed.It is therefore necessary to pay

special attention to:

- The correct use of materials, instruments and equipment:

before carrying out any sort of operation, read the instruction

manuals carefully and follow the accident prevention and safety

instructions with great care.

The workplaces for carrying out operations,

which should have appropriate ventilation systems which satisfy

the legal requirements concerning air exchange, the filtration of

harmful substances (solvents) and the reduction of dust levels;The handling of dangerous substances which

should be carried out in accordance with the supplier's instructions and

recommendations;The collection and disposal of refuse which

should be carried out in accordance with the laws in force.When working with and handling harmful and

dangerous substances, the appropriate safety equipment should be employed

(clothing, masks, gloves, goggles, etc.).

Vehicle repair operating cycles

The vehicle repair operating cycles

usually consist of the following stages:

- checking the vehicle measurements;

- cutting/removing damaged elements and preparing the

bodyshell for welding;

- welding replacement elements;

- preparing for painting;

- painting;

- renewing the anti-corrosion treatments;

- sound insulation, sealants.

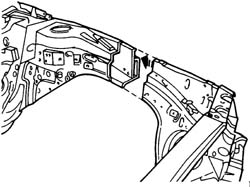

CHECKING AND RESTORING THE VEHICLE MEASUREMENTS

This is the first stage in the

repair process in which the distortion suffered by the bodyshell

is measured and evaluated and the components involved are identified.During this stage the first actual repair

operation is carried out: pulling the bodyshell to restore the measurements before

cutting and removing the damaged elements.

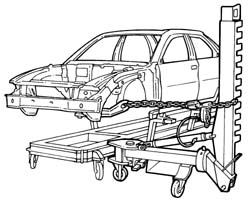

PULLING THE BODYSHELL

Pulling the bodyshell, to restore

the measurements, is carried out on straightening benchs where it

is possible to secure the bodyshell using vices and attachments

which should be fixed according to specific methods for each vehicle,

with instructions provided by each supplier.Jigs are used to check the measurements

of the bodyshell. They are positioned at specified points, and are

used to check the measurements indicated by the jig manufacturer for

each model, or alternatively the vehicle's own measurements given

in the section 'Descriptions and Operation'.Example of a possible straightening bench

configuration.

General repair instructions

| Before carrying out any sort of

operation on the vehicle, disconnect the battery terminals. |

For safety reasons and for a better

quality repair, IT IS PROHIBITED TO:

- replace structural parts of the bodyshell without using a

repair bench. The use of the bench makes it possible to guarantee

the restructuring of the vehicle with the original manufacturing

measurements, ensuring the correct position of the forecarriage

and back-carriage elements.

- heat the structural parts of the bodyshell to straighten them.

- cut and weld, edge to edge, any bodywork element and

reinforcement on the same line.

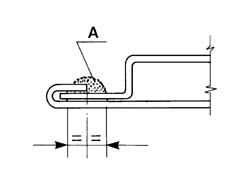

Remove the damaged elements, cutting them

on the joins, following the cutting lines given in the Service Manual. Carried

out correctly, the operation involves wasting a few centimetres

between the two cutting lines in order to improve the distribution

of the fusible points created by the welding.The diagram below illustrates a possible

implementation.

General repair instructions

| The removal of the damaged elements

is the repair operation during which the potentially most dangerous

equipment is used. Before carrying out any operation, read the safety

instructions in the manual very carefully and follow the warnings

from the manufacturer of the equipment in conjunction with the safety

and accident prevention recommendations. |

The use of the following is required

for the removal of damaged body panels:

- hack-sawing machines;

- circular saws;

- power chisels (only in case of need);

- plasma-arc cutting systems;

- electric drills;

- milling machines;

- grinding machines;

- dolly blocks and hammers;

- disc grinding wheels;

- air purifiers / extractor systems.

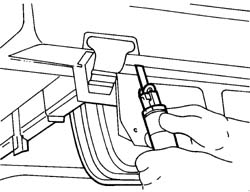

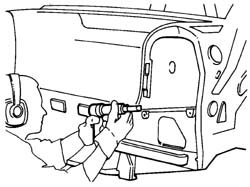

HACK-SAWING MACHINE

This type of saw makes it possible

to carry out fast and precise cutting, with the possibility of regulating

the speed of the blade to suit different situations.Example of the use of a hack-sawing machine

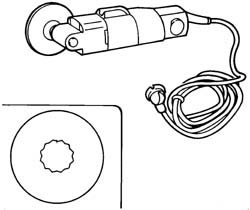

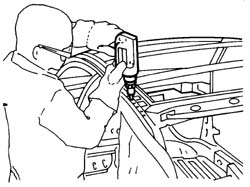

OSCILLATING CIRCULAR SAW

An oscillating saw is used in

cases where high cutting precision is required; for example, when

you need to replace the sheet metal of a box section that is laid

over a panel which must not be damaged. By adjusting the speed and the

number of oscillations it is possible to achieve the precision required

according to the conditions of use. The high level of safety of

this instrument makes it advisable to use it as an alternative to

other types of saws.Example of an oscillating circular saw

POWER CHISEL

A pneumatic chisel is used to remove

parts of body panels; it is advisable to use it:

- when it is not possible to use a power saw, milling machine

or drill; for example, when a panel that must not be damaged lies

behind the panel that requires cutting;

- when it is possible to directly separate the welded panels,

inserting the power chisel between the two panels along the join

edge in order not to leave edges which need removing later on.

The different attachments increase its versatility.Example of the use of a power chisel

PLASMA-ARC CUTTING SYSTEM

This cutting system, achieved

through the combined effect of an electric arc and gas or a mixture

of gases, is used whenever it is necessary to cut rather large panels. Depending

on the thickness of the panel and the depth of the cut, adjust the

current and the gas flow following the instructions in the Manufacturer's

booklet. | The use of a plasma-arc cutting

system requires the use of an extractor system to get rid of the fumes

and harmful gases. |

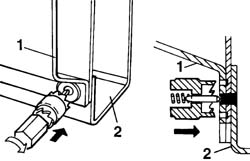

ELECTRIC DRILL

An electric drill is normally

used in cases where a milling machine cannot be used; the correct

use of the drill to remove spot welds if several panels are superimposed

is illustrated in the diagrams below. The attachment to be used

in these operations is identical to the one fitted on the milling

machine. The spot weld should be marked using a drift, in order

to provide a support point for the centring bit, this prevents the

drill moving away from the spot and damaging the surrounding area;

force should be exerted on the cutter until the depth reached is

slightly greater than the thickness of the panel which should be

removed (see diagram below).Example of the use of an electric drill

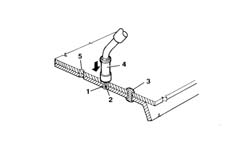

ELECTRIC DRILL

Example of the correct usage

of a milling cutter

1. Panel to be removed.

2. Box section panel preventing the use of a milling cutter.

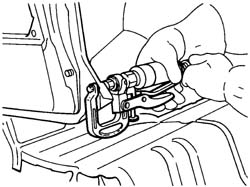

MILLING CUTTER

A milling cutter for removing

weld spots should be used after cutting the panel to be replaced

in order to allow the removal of the panel offcuts remaining on

the edges of the bodyshell.The milling cutter acts on the panel which

constitutes the offcut, cutting it as far as the panel underneath

and thereby isolating the spot weld.After the reduction of all the spot welds.

the offcut is removed using pliers.To facilitate the operation, use a cutting

speed of around 1000 rpm.Adjust the depth of the cutting using the

special screw.Example of the use of a milling cutter

MILLING CUTTER

| Do not drill matching components.

If holes are made by mistake, close them by (MIG) welding. The presence

of holes reduces the strength of the component involved and can

also give rise to the penetration of water and corrosive agents. |

DOLLY BLOCKS AND LEVERS

These instruments are used when

panels need to be straightened by beating, in order to have a counter-action point

to support the panel. Dolly blocks are designed so that they adjust

to the different panel conformations and, when the working area

permits, they can replace a hammer.Levers are used in the same way as dolly

blocks, however they are designed so that they can be introduced

through restricted openings and spaces to get to areas which are difficult

to reach.Dolly blocks and levers are also used to

eliminate distortions from the edges of panels which are not removed thereby

allowing correct matching with the replaced panels, avoiding weakening

the structure.

Welding replacement elements

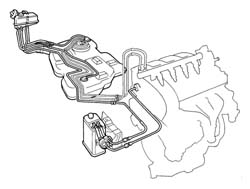

If welding operations or work

which could produce flames near the fuel system components illustrated

in the diagram or other flammable parts of the vehicle need to be

carried out, the parts involved must be removed from the vehicle and

the free pipe connections sealed if the connectors are removed.

Disconnect the electronic control units (I.E., ABS, Air Bag, Air

conditioning, Alarm, etc.) which could be damaged during the work.Parts of the fuel system

Welding replacement elements

Welding bodywork elements should

be carried out, according to requirements, using different methods:

- Spot welding;

- Seam (MIG) welding;

- Brazing.

EQUIPMENT

The following equipment is used for

these operations:

- welding guns;

- seam (MIG) welders;

- oxyacetylene torches (brazing).

INTRODUCTION TO ELECTRICAL SPOT WELDING

In electrical spot welding the

heat needed to melt the metal is supplied by the resistance to the

current flow provided by the actual metal.Spot welding is carried out to panels where

the join edges overlap and the panel metal melts; no metal filler

is therefore needed for this type of welding. In areas where three or

more panels overlap, spot welding should be repeated for a second

time.The type of join produced is not continuous;

to create a join with good mechanical strength the spot welds must

be correctly spaced following precise instructions (see tables below).

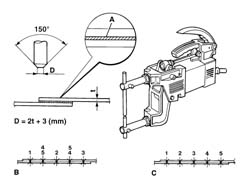

SPOT WELDING

In the case of spot welding, check::

- that the arms are correctly aligned;

- that the diameter of the edges of the electrodes is

correct;

- the planarity and that the weld edges are correctly matched;

- that the welding sequence is correct.

| Before welding, apply electro-weldable

galvanizing protection to the edges of the join to protect the box

sections from corrosion. |

Spot welder, geometric characteristics of

the electrode according to the thickness of the panel and the welding sequence.

A. Electro-weldable galvanizing protective

B. Correct welding sequence

C. Incorrect welding sequence

D. Electrode dimensions

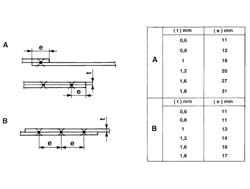

SPOT WELDING

Table of reference values for

carrying out spot welds.

A. Table for determining the distance of the spot welds from

the edges of the panels according to their thickness.

B. Table of reference values for the correct spacing of the spot

welds according to the thickness of the panel.

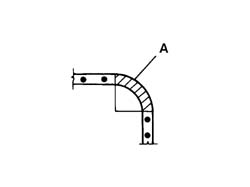

SPOT WELDING

Do not weld on angular shaped

surfaces. Welding on this type of surface would create a concentration

of tension which would result in breakage.Example of correct spot welding at corners.

A. Area where welding should not be carried out.

SEAM (MIG) WELDING

MIG welding should be used for parts

where spot welding cannot be used. When carrying out seam (MIG)

welding, check:

- the speed

- that the seam weld beads have been correctly made (alternating

weld sections)

In this welding system (automatic advance

seam) a protective inert gas atmosphere is used (hence the name

M.I.G. which stands for Metal Inert Gas).The continuous progress of the seam (which

constitutes both the electrode and the filler metal), allows long

welds to be made without interruption. The flow of inert gas sent to

the welding area eliminates the surrounding air preventing the oxidation

of the metal and therefore has the function of providing a protective

layer for the weld. For these reasons, MIG welding differs from

welding carried out with a covered electrode through the absence

of dross on the welding bead; also there are no pores which can occur

during normal arc welding. | The use of MIG welding requires

an extractor system to get rid of the fumes and harmful gases. |

OPERATING METHODS

In order to weld two panels correctly

using a MIG welder: grind or pickle the panel thoroughly, place

the equipment in a sensible position so that whilst carrying out

the welding the outer casing of the torch does not become twisted

or assume positions which could hinder progress, wear protective

clothing and a suitable mask with non-actinic glass (glass standard

no. 8 for currents of 40/60A and no. 9 for currents of 80/200A).

Make sure that there is good electrical contact. Adjust the gas

flow according to the instructions of the equipment Manufacturer.

Make two spot welds at the two edges of the join line and one at

the centre, then carry out spot welds in the middle of the two sections

defined in this way. The spot welds should be 25-30 mm apart.The diagram below illustrates correct welding. | the correct gap is about 1 mm. |

Carrying out a weld using inert gas (MIG)

for joining two matched panels.

OPERATING METHODS

It is not advisable to initially

carry out a seam weld because, in addition to being difficult to

do, it can cause distortion of the panel through the accumulation

of heat involved.The difficulty in carrying out a weld with

a single bead lies in the need to move the torch fairly slowly in

order to achieve good weld penetration which is also quick enough not

to incur the risk of 'burning' the panel.Moving the torch too quickly also results

in a poor weld bead content because after the subsequent operations

of grinding the bead the layer of material remaining is not sufficient

to guarantee the resistance of the join.After the initial spot welding of the panel,

the spot welds should be ground to the level of the panel using

a rigid disc grinder.At this point the alignment of the panels

should be checked and, if necessary, corrected using a hammer and

steel dolly block.Then proceed with filling the gaps between

the various spot welds carrying out alternating welding sections, keeping

the torch at an angle of around 60°, (see diagram above).1. Tacking the join. The inset shows the

tack welds at the rear of the panel. Grinding join tack welds.2. Carrying out the welding.3. Two alternatives are illustrated for

the correct sequence of welding to be carried out to avoid deformations

of the panel.The fact that the weld has been carried

out correctly is confirmed from the rear of the weld bead which

should show a series of spherical bumps along the entire length

of the join.The MIG welder can also be used for joining

overlapping panels where only one side is accessible.To carry out the welding, the panels must

adhere perfectly and the torch should be kept perpendicular to the

surface.In this way the action of the electrode

melts the first panel initially, then the second producing a crater

which is filled.In order to carry out this operation correctly,

the welding machine must be adjusted to the correct current value

for the thickness of the panels being worked on and pressure must

be applied to the surface, with the torch resting on its supports,

to faciliate the matching of the panels.Where the thickness of the panels is more

than 1.5 - 2.5 mm, holes 0.6 mm in diameter must be made level with

the weld spots.Carrying out inert gas (MIG) welding to

join overlapping panels

1. Area where panels are joined

2. Electrode

3. Weld spot

4. Torch

5. Hole (only for thick panels)

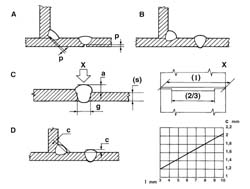

GENERAL INSTRUCTIONS FOR EXPOSED WELDING

Below are some important instructions

not be underestimated:

- incomplete penetration (p) should be 15-30% of the thickness

of the panel (see diagram below - point A incorrect welding, point

B correct welding).

- the height of the bead (a) should be 60% of the thinnest

thickness (s), the clearance (g) between the panels before welding

should be 20% of the thinnest thickness for at least two thirds

of the length (l) of the bead, (see diagram below, point C and detail

X). The diagram indicates the value of the convexity (c) of the

bead according to the length (l) of the weld.

- the shape of the bead section should have a convexity (e)

which depends on the length of the actual bead (see diagram below,

point D).

Examples of welding.

BRAZING

Brazing is only used if the panels

being replaced have been welded by this method, with the welding

only carried out at the points defined by the Manufacturer.This type of welding does not guarantee

mechanical properties which are comparable with the other systems described

previously and therefore are not applicable for joining structural

parts. | When using oxyacetylene torches

for brazing, follow the safety instructions relating to their usage

and be sure to work in a safe environment. The use of this welding

system requires the use of an extractor system to get rid of the

fumes and harmful gases. |

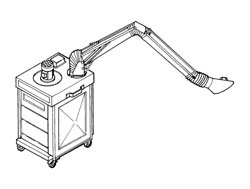

AIR FILTRATION AND PURIFICATION SYSTEM

When carrying out operations

which produce fumes, gases and dust which is dangerous to the operator,

air filtration and purification systems must be used.These systems are adapted to suit the varying

requirements and their size depends on the volume of air to be purified. These

systems usually operate through the combined action of mechanical

and electro-static filtration and purification through active charcoal.

Filtration takes place in two stages: mechanical elimination, using

wire gauze, of the largest particles of dust subjecting the flow

of air to ionization which statically charges the particles of dust which

are then eliminated from the flow through the electro-static process.The air flow is then purified by passing

through active charcoal filters. In addition to their efficiency,

handling and noise levels in these systems has been improved so that

they never create a nuisance.The diagram below illustrates a possible

conformation decribed above.Example of a portable air filtration and

penetration system

Introduction

Painting the bodyshell has two

fundamental objectives; protecting the surfaces of the panels from

environmental attack and, from an aesthetic point of view, producing

a shiny, bright colour.The large number of chemical products used

in painting operations requires special care to be taken over their

handling and usage.These painting operations involve the emission

of paint fumes and solvent vapours which, if inhaled by the operators,

can seriously affect their health and they should only be carried

out in special spray booths.The operator should always wear a mask and

protective clothing.These masks can be the filtration type for

brief operations and the total protection pressurized type for longer

operations.

EQUIPMENT

The following equipment is used during

painting operations:

- filltration masks and protective clothing;

- masking materials and tape;

- spray booths and drying ovens;

- spray guns;

- infra-red lamps;

- polishers;

PROTECTIVE CLOTHING

When carrying out painting operations,

suitable clothing should always be worn, so that the operator is

well protected from contact with harmful agents.It is also advisable to use a barrier cream

applied to the most exposed uncovered areas (face, hands and arms) which

should be removed at the end of the painting operations. be removed

at the end of the painting operations.

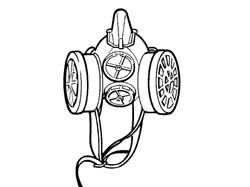

FILTRATION MASK

This type of mask only protects

the operator's respiratory tracts, so goggles and hair protection

should also be used at the same time. Its use is recommended for

small retouching operations.Example of a filtration mask.

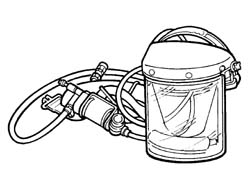

PRESSURIZED MASK

This mask guarantees protection

of both the face and hair and is supplied with pure air via the

compressed air system which operates the spray gun.The air is further purified with a degree

of separation approaching 100% by an active charcoal filter fitted

to the operator's belt.The slight excess pressure created inside

the helmet prevents the infiltration of paint vapours.The use of this mask is advisable for lengthy

painting operations. Example of a pressurized mask

SPRAY BOOTH

Painting and drying operations

for prepared parts should be carried out in spray booths. If the

extent of the damage repaired is medium to large, it is advisable

to use a special spray booth and a hot air oven for drying the paint.The workplace must be equipped with an air

conditoning system and filtered by purifiers, mainly consisting

of renewable active charcoal filters.The optimum painting conditions which

should be maintained in the booth during painting are as follows:

- constant temperature of between 22 -25 ° ?

- constant humidity of between 75-80%

The workplace in question can be:

- a combined type spray booth and drying oven;

- a separate type spray booth and drying oven.

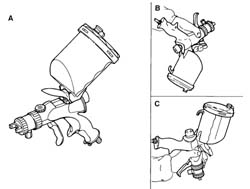

SPRAY GUNS

The development of ergonomics

and spraying techniques has led to the definition of a new type

high air volume and low atomization pressure spray gun where the

paint mist is considerably reduced. This type of spray gun is lighter with

a grip designed to reduce tiredness and the onset of cramp and has

a trigger which requires far less effort than traditional spray

guns. The handling of the spray gun has also been made easier through

the balance and the reduced visual restriction which allows greater

control when working. The most interesting aspect of this spray

gun is the supply system which allows painting in any direction, even

with the reservoir pointing downwards, also improving cleaning procedures

with a considerable saving in time and materials. The possibility

of painting from above or below in addition to preventing the formation

of areas which are either too wet or too dry, facilitates access to

areas of the bodywork which are difficult to reach. Special attention

has been paid to the ease of adjustment which requires minimal,

simple movements. This type of gun combines great efficiency with

a very refined atomization capacity for any produce, even those

which are water-soluble and is used at pressures of 0.7 g (10 PSI)

or less. Thanks to these capacities for exploiting the painting material,

considerable savings are achieved in financial terms and the working

environment is improved. The diagram below illustrates several possible

ways of using the gun.Using a spray gun

A. Normal method of use

B. Use from the bottom to the top

C. Use from the top to the bottom

PORTABLE INFRA-RED LAMPS

If the operation only involves

small retouches, the use of a drying oven is not advisable. In these

cases the paint can be dried using special infra-red lamps fitted

on parabolid mirrors. The use of one or more lamps positioned in

such a way that an even temperature is produced on the surface of

the area retouched, allows the drying of the paint film and produces

results which are comparable to those obtained in drying ovens.These types of lamps considerably reduce

the drying times, also reducing energy consumption. The lamp should

only be used when the paint has undergone a degree of drying so

that it is 'outside the powder' condition.Drying a retouched area using a portable

infra-red lamp

POLISHERS

The operation of polishing the

paint should only be carried out after drying the enamel and after

the base has cooled down to ambient temperature.Polishing is also necessary if there are

defects in the paintwork such as dust, paint fumes, drips, orange

peel, small scratches.There are many products designed to eliminate

these defects which should be applied either manually or mechanically,

using a polishing machine.The tool should be held parallel to the

surface to be polished and should not be held at an angle, to avoid

the paint overheating and the creation of circular, concentric grooves.The diagram below illustrates the correct

way of holding the polisher.Correct use of a polisher

Painting cycles

| When using chemical products,

follow the safety instructions from the supplier closely. |

The painting operations vary according to

the type of operation.The sequence of operations is described

in the paragraphs which follow. There is a special procedure for

the colour 'Nuvola (cloud) Light Blue'.

PAINTING A REPLACED BODY PANEL (BOLTED)

With the original part treated

with cataphoresis on electro-galvanized panels.1. Clean the replacement panel, to remove

any traces of dust, grease, etc. using a 'VOC' low volatile organic

compound detergent product.2. Carry out a slight 'surface' dry sanding

using P 220 - P 240 grade abrasive paper, using a power sander equipped with

a suction system only on the panel being painted.3. Suction the dust and clean with a low

'VOC' detergent product or an anti-silicone product.4. Apply a chrome-free passivating product

(wash primer) in a single coat to the areas stripped following the

instructions from the supplier.5. Apply sealant through extrusion to visible

panel joins/matches following the supplier's instructions (for the

subsequent application of the filler).6. Apply the high/medium solid filler, prepared

previously, following the supplier's instructions.7. Finish off using P320 - P400 grade abrasive

paper using a sanding machine fitted with a suction system and repeat operation

3.8. Blow through the entire panel thoroughly.9. Clean the surface with an anti-static

cloth.10. Apply the pastel/metallic/metallescent

base tint, prepared previously, following the supplier's instructions.11. Apply the normal or high solid twin

component acrylic clear coat, prepared previously, following the

supplier's instructions. | Check the panel and, if there

is a slight dent, fill the part concerned with filler, then dry

sand it using P 320 - P 400 grade abrasive paper using a sanding

machine fitted with a suction system. Repeat operation 3/4. |

PAINTING A REPLACED BODY PANEL (WELDED)

With the original part treated

with cataphoresis on electro-galvanized panels.1. Clean the (welded) replacement panel

to eliminate any dust, grease, etc. using a low 'VOC' detergent

or an anti-silicone product.2. Dry sand the areas involved in the welding

with P 80 - P 120 grade abrasive paper using a sanding machine fitted with

a suction system.3. Carry out a slight 'surface' sanding

using P 220 - P 240 grade abrasive paper using a sanding machine

fitted with a suction system only on the panel involved in the painting.4. Suction the dust and clean with a low

'VOC' detergent product or an anti-silicone product.5. Apply a chrome-free passivating product

(epoxide base coat) to the stripped areas following the supplier's

instructions.6. Fill the join areas involved in the welding

with polyester filler, following the supplier's instructions.7. Dry sand with P 100 - P 120 grade abrasive

paper using a sanding machine fitted with a suction system and carry out

operation 4/5.8. Apply sealant through extrusion to visible

panel joins/matches following the supplier's instructions (for the

subsequent application of the filler).9. Apply the high/medium solid filler, prepared

previously, following the supplier's instructions.10. Finish with P 320 - P 400 grade abrasive

paper using a sanding machine fitted with a suction system and repeat operation

3.11. Clean the surface with an anti-static

cloth.12. Apply the pastel/metallic/metallescent

base tint, prepared previously, following the supplier's instructions.13. Apply the normal or high solid twin

component acrylic clear coat, prepared previously, following the

supplier's instructions. | Check the panel and, if there

is a slight dent, fill the part concerned with filler, then dry

sand it using P 320 - P 400 grade abrasive paper using a sanding

machine fitted with a suction system. Repeat operation 4-5. |

PAINTING A (REPAIRED) BODY PANEL

1. Dry sand the 'repaired area'

with P 80 - P 180 grade abrasive paper using a sanding machine fitted

with a suction system.2. Suction the dust and clean with a low

'VOC' detergent product or an anti-silicone product.3. Apply a chrome-free twin component passivating product

(epoxide base coat) to the repaired area in a single coat, following

the supplier's instructions.4. Fill the areas with air drying twin component

polyester filler.5. Dry sand with P 100 - P 120 grade abrasive

paper using a sanding machine fitted with a suction system and carry out

operation 2/3.6. Apply the high/medium solid filler by

shading in the filled area prepared previously, following the supplier's instructions.7. Dry sand with P 320 - P 400 grade abrasive

paper using a sanding machine fitted with a suction system and carry out

operation 2.8. Blow through the entire panel thoroughly.9. Clean the surface with an anti-static

cloth.10. Apply the pastel/metallic/metallescent

base tint, prepared previously, following the supplier's instructions.11. Apply the normal or high solid twin

component acrylic clear coat, prepared previously, following the

supplier's instructions. | Check the panel, if there is a

slight dent, fill the part concerned and then dry sand with P 320

- P 400 grade abrasive paper using a power sanding machine fitted

with a suction system. Repeat operation 2/3. |

PAINTING (REPLACEMENT) BUMPERS

1. Clean the bumper ordered from

the Parts Division to remove any traces of dust, grease, etc. using

an anti-static product because it is protected by a special base

coat for the subsequent painting.2. Rub down the surface to be painted, with

P 360 - P 400 grade abrasive paper, using a sanding machine fitted

with a suction system.3. Suction the dust and clean using a low

'VOC' anti-static product.4. Blow through the entire panel thoroughly.5. Clean the surface with an anti-static

cloth.6. Apply the chrome-free twin component

passivating product (plastic base coat) to all the stripped areas

in a single coat, following the supplier's instructions.7. Apply the pastel/metallic/metallescent

base tint, prepared previously, following the supplier's instructions.8. Apply the normal or high solid twin component

acrylic clear coat, prepared by the supplier. | Add elasticized clear coat, following

the supplier's instructions. |

PAINTING A PLASTIC(REPLACEMENT) ELEMENT (KMC COMPOUND

MATERIAL)

1. Clean the screwed (plastic)

part ordered from the Parts Division to remove any traces of dust,

grease, etc. using a low 'VOC' detergent product or an anti-silicone

product.2. Carry out a slight 'surface' dry sanding,

only on the plastic involved with the painting, with P 220 - P 240 grade

abrasive paper using a sanding machine fitted with a suction system.3. Suction the dust and clean using a low

'VOC' detergent product.4. Apply high/medium solid filler, prepared

previously, following the supplier's instructions.5. Finish off with P 320 - P 400 grade abrasive

paper using a sanding machine fitted with a suction system. Repeat operation

3.6. Blow through the entire panel thoroughly.7. Clean the surface with an anti-static

cloth.8. Apply the pastel/metallic/metallescent

base tint, prepared previously, following the supplier's instructions.9. Apply the normal or high solid twin component

acrylic clear coat, prepared previously, following the supplier's instructions. | Check the panel and, if there

is a slight dent, fill the part concerned with filler, then dry

sand it using P 320 - P 400 grade abrasive paper using a sanding

machine fitted with a suction system. Repeat operation 3. |

PAINTING A NON REPLACED BODY PANEL/PLASTIC (KMC) ELEMENT

'COSMETIC CYCLE'

1 . Dry sand the panel with the

defect in the PV applied, with P 360 - P 400 grade abrasive paper,

using a sanding machine fitted with a suction system.2. Suction the dust and clean the panels

with low 'VOC' detergent or with an anti-silicone product, whilst

a low 'VOC' anti-static product should be used for plastics.3. Blow through the entire panel thoroughly.4. Clean the surface with an anti-static

cloth.5. Apply the pastel/metallic/metallescent

base tint, prepared previously, following the supplier's instructions.6. Apply the normal or high solid twin component

acrylic clear coat, prepared previously, following the supplier's instructions.

PAINTING REPLACEMENT OF REPAIRED PANELS USING SPECIAL

'NUVOLA' MICALIZED ENAMEL

'Nuvola' micalized enamel is

a special colour with a CHANGING/PEARLESCENT appearance. The iridescent

effect is achieved through a special enamel containing particles

of mica coated in iridescent colourings; this type of enamel is

an almost transparent paint which adds a pearlescent appearance

to the base colour which shows through and gives the tone.

PAINTING A REPLACEMENT PANEL (WITH THE ORIGINAL PART

TREATED WITH CATAPHORESIS)

Operating cycle for 'Nuvola'

micalized enamel with iridescent colourings.1. Clean the replacement panel to remove

any traces of dust, grease, etc. using low 'VOC' detergents.2. If there is accidental rust due to storage,

grind the area until the panel is stripped.3. Slightly dry sand the 'surface' of only

the part of the panel involved in the painting, using 220 grade

abrasive paper using a sanding machine fitted with a suction system.4. Clean the exposed part of the panel using

a low 'VOC' detergent.5. Blow through the entire panel with compressed

air.6. Apply the chrome-free twin component

passivating product by spraying in a single coat. (film thickness

from 5....10 micron).7 . Apply plastic sealants to the joins

where applied originally (see specific cycle in Notes chapter).8. Apply High Solid twin component filler,

by spraying in two cross coats, with an interval of several minutes according

to the desired thickness.9. Wait for 10 - 15 minutes before starting

the drying.10 . Dry the primer in an oven at a temperature

of 40°....60° ? f?? 30 - 40 minutes. (Film thickness from 70....80

micron; hardness F-H).11. Dry sand the element sprayed with suction

using 400 grade abrasive paper. Make sure that the element is at ambient

temperature for this operation.12. Blow with compressed air.13. Clean with low 'VOC' detergents and

polish with an anti-static cloth.14. Apply a cross coat of twin layer pastel

enamel.15. Dry for 10-15 minutes at ambient temperature

(20° ?) and then dry in an oven at a temperature of (60° ?)

for 40 minutes.16. Dry sand the element sprayed with suction

using 800 grade abrasive paper. Make sure that the element is at ambient

temperature for this operation.17. Blow with compressed air.18.Clean with low 'VOC' detergents and polish

with an anti-static cloth.19. Apply the 'Nuvovla' base coat by spraying

one light coat and four normal coats at intervals of several minutes then

follow with a light, faded-in coat to even the paint (film thickness

around 30 micron).20. Drying for 15-20 minutes at a temperature

of 20° C.21. Application of normal or high solid

twin component acrylic clear coat.22. For normal clear coat: spray a light

coat followed by two coats at intervals of several minutes.23. For High Solid clear coat: spray a light

coat followed by another coat with an interval of several minutes.24. Dry for 15......20 minutes at ambient

temperature (20° ?) and then dry in an oven at a temperature of

60° C for 40 minutes (film thickness 40....50 micron; hardness

HB-F).25. Possible mechanical or manual polishing

of the retouch or the painted panel (or the adjacent area) with

fine grade abrasive paste and/or polish. | It is advisable to carry out this

operation at least 24 hours after drying. |

PAINTING A REPAIRED - RETOUCHED PANEL (OPERATION

ON BARE PANEL)Operating cycle for 'Nuvola' micalized enamel

with iridescent colourings.1. Sand the area to be retouched using 150

- 220 grade abrasive paper taking care to level the surrounding

area and eliminate any traces of corrosion on the exposed panel.2. Clean the exposed part of the panel and

the surrounding area overhauled with low 'VOC' detergent.3. Blow through with compressed air.4. Apply the chrome-free twin component

passivating product to the exposed areas of the panel by spraying

in a single coat. (Film thickness from 5 - 10 micron).5. Possible filling with air drying twin

component polyester product.6. Dry overhauling with suction of the area

filled with 80 - 120 grade abrasive paper.7. Blow through with compressed air.8. Wash the sanded area with low 'VOC'

detergents.9. Further application of the twin component

passivating product on the areas of the panel exposed during sanding by

spraying a single coat.10. Application of High Solid twin component

filler by spraying 2....4 cross coats, with intervals of several

minutes according to the desired thickness.11. Wait for 10 - 15 minutes before starting

the drying.12. Drying of base coat with infra-red lamps.13. Initial distance 50 - 60 cm. for a period

of 5 minutes; then place the lamp 35 - 40 cm away for 15 minutes.

(Film thickness from 80 to 150 microns). hardness F-H). Alternatively,

dry in an oven at a temperature of 60° C for 40 minutes.14. Dry sand the element sprayed with suction

using 400 grade abrasive paper. Make sure that the element is at ambient

temperature for this operation.15. Blow with compressed air.16. Clean with low 'VOC' detergent17. Polish with an anti-static cloth.18. Carry out the cycle for replacement

panels from point 1.12 to point 1.20.PAINTING THERMO-PLASTIC MATERIAL COMPONENTS

(OPERATIONS ON REPLACEMENT PARTS)On the model in question, these parts are

the: Bumper, Spoiler and Miniskirts.Operating cycle for 'Nuvola' micalized enamel

with iridescent colourings.1. Apply the adhesion promoter (primer)

for thermo-plastic materials.2. Carry out the cycle for replacement panels

from point 1.12 to point 1.20.

PAINTING THERMO-HARDENING MATERIAL COMPONENTS (OPERATIONS

ON REPLACEMENT PARTS)

On the model in question, the

part involved is the fuel filler. Operating cycle for 'Nuvola' micalized enamel

with iridescent colourings. Carry out the cycle for replacement panels

from point 1.7 to point 1.20.  | All the operations of sprying

the passivating product, the filler and the enamels should be carried

out in a spray booth after having masked the area surrounding the

component involved. Base coats, filler, enamels and solvents should be

handled and used in well ventilated areas. Special solvents with

a maximum of 3% toluene and xylene should be used for cleaning the equipment.

Before carrying out any polishing, make sure that the panel and

he surrounding area are at ambient temperature. Before spot welding

panels, apply electro-weldable galvanizing protective (PPG D 386

- 459632 or an equivalent product) to the ground edges of the join

area. |

Renewing the anti-corrosion treatments, sound insulation

and sealants.

The treatments to which the bodyshell

is subjected to achieve the necessary resistance characteristics

to corrosion, sound insulation and sealing can be damaged or destroyed

by repair operations.They should therefore be renewed, as appropriate

during the repair operations, so that the vehicle is restored to

its original condition.

EQUIPMENT

The following equipment is used:

- power guns for sealant product extrusion;

- foam injection systems;

- wax based oil injection systems;

In box sections which have been replaced

or repaired by welding or overheating, the internal anti-corrosion

protection must be renewed through:

- the application of rust converter in the overheated

or welded areas which require drying for at least 24 hours at ambient

temperature (20 ° C);

- the application of wax based protection in the replaced or

repaired box section (type PPG 853.764 or equivalent product);

Renew the rigid type expanded polyurethane

foam in the box sections (e.g.: Schiuma - fix from BOSTON, Schiumal

P.U.R. from TORGGLER - Merano or an equivalent product);Where necessary, restore the sealing of

the joins;Carry out the sealing, following the instructions

given below, in the flanges of the moving parts (tailgates, lids) supplied

as spares: on a replaced component treated with cataphoresis, clean

the areas involved with heptane or anti-silicon/anti-static solvents;Apply a bead of SIKAFLEX 221 type polyurethane sealant

manufactured by SIKA (*) in the shape and position illustrated in

the diagram.- Leave the sealant to dry for 24 hours

at ambient temperature (20 ° ?) or 40 minutes at 60 ° C; - Carry

out the normal painting of the component. Apply sound-deadening

paint on external parts which have been replaced or repaired, as

required.(*). Alternatively, use a similar product

manufactured by 3M or other equivalent products, following the supplier's instructions.Example of application of sealant