3022423 - 1080E evaporation control system

OPERATION

The vapours coming from the tank through the two float valves (1) are sent to the separator (2).The vapours condensed in the separator fall back into the tank.Uncondensed vapours are sent through the pipe (3) to the canister (4), where they are absorbed and stored by the activated charcoal.The vapours pass to the inlet box through the solenoid (5) controlled by the fuel injection control unit.Multi-function valves

The multi-purpose valves have the following functions:

- pressurizing the tank

- ventilating the tank

- retention

- seal in the event of roll-over

Under particular driving conditions, a vacuum could be created in the tank because of:

- temperature changes

- fuel consumption.

Canister

Mounted in the front right wheelarch, this consists of an activated-charcoal filter element which absorbs the fuel vapours coming from the separator.A one-way valve allows external (scrubbing) air to enter during vapour intake.

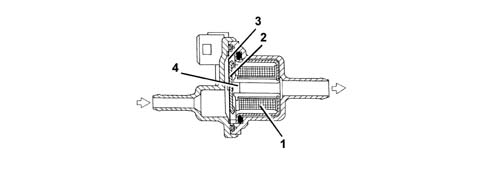

Fuel vapour solenoid

It is fitted in the lower part of the intake manifold and is controlled by the injection control unit.The function of the solenoid is to allow fuel vapours stored in the engine intake canister through to the engine intake.If there is no supply, the solenoid is in the open position; when the ignition key is in the ON position, the solenoid closes, ready for operation.If energized, the electromagnet (1) attacts the shutter (2) which overcomes the load of the flat spring (3) and closes the hole (4), preventing the passage of fuel vapours.