3363690 - INTRODUCTION - ENGINE

GLOSSARY

Hardened and tempered steel

Heata treatment applied to special steels to improve their mechanical properties: it involves hardening followed by tempering to make the material much stronger.Tempering: consists of heating at temperatures < 720°C followed by slow cooling in order to lessen the effects of the tempering without removing them.In this way, the material returns to conditions that are closer to a stable chemical and physical balance.Hardening: this is achieved when the metal structure is at a high temperature when it is harder and more resistant than when cold.CONTROL AREA NETWORK (CAN)

The CAN is a communication network that allows the transmission of data between the ECU and other vehicle system computers.The advantage of this system lies in the fact that the need for long wiring is contained and the numberof sensors reduced (because, from the moment the computers are connected by the data transmission system, the information supplied by a sensor can be used simultaneously by various devices).The CAN also allows an improvement in the fault diagnosis system capacities, faster transmission of signals and the electrical/magnet compatibility of components (relation betwen various electrical and electronic circuits on the vehicle and interaction between the vehicle and surrounding conditions).The circuit that connects the ECU with the other terminals is an integrated circuit known by the CAN interface terminal. It has the function of converting the messages received via the data transmission system into the appropriate format.Condensation

This is the change of a substance from a vapour to a liquid state, the opposite of evaporation; it takes place through comprssion or cooling.TIMING

Numerous components (ignition - timing - injection) work in synchronism with the movement of the pistons, therefore they must be perfectly "timed" with the crankshaft to which they are connected by toothed belts or chains.The timing of the ignition is the angular link between the position of the piston and the moment in which the spark strikes (ignition advance).The timing is designed to determine the moment of the opening and closing of the valves in relation to the position of the piston.The injection timing is designed to determine the moment of the opening of the injector in relation to the position of the piston.DUCTILE CAST IRON

Ductile cast iron is cast iron that, through the effect of the addition of cerium and magnesium contains globules or balls of carbon in a graphite state in a predominantly ferrous matrix with the consequent improvement of all mechanical and techological properties making it forgeable, weldable and workable using tools.It is used very extensively also because, unlike normal cast iron, it has high resistance and percentage extension values.Evaporation

The phenomenon, also known as vapourization, when a body changes from a liquid state to a gaseous state.Occurs at any temperature. The lower the temperature, the slower the change.MISFIRE

This is the failed ignition of the (air/petrol) mixture inside the combustion chambers.This phenomenon produces irregular operation, particularly noticeable during idling and at low speeds.The consequent escape of unburnt petrol in the exhaust has negative effects on the life of the catalytic converter.PWM MODULATION OPERATING CYCLE

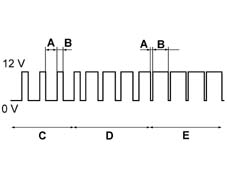

This is an impulse frequency and modulated width fixed tension produced by the ECU for the operation of the actuators. A PWM (Power Width Modulation) voltage supply consits of a series of single polarity square waves whose duration is altered by the ECU in response to demand.

Sensor

It is a system that reacts when subject to any form of energy by changing its state, i.e. one or more of its properties (resistance, volume, temperature etc.).For example, a sensor is a material that undergoes conductivity changes when submerged in a magnetic field.New-generation sensors are solid-state devices produced using microchips that can take readings from their surroundings and produce a response in the form of electrical signals that can be processed so a final action can be taken.Sensors are therefore able to measure force, acceleration, pressure and temperature of gases, liquids and solids, concentration of gases such as nitrogen oxides, oxygen, etc.Viscosity

Material property whereby the particles in a body encounter resistance as they slide over one another.The resistance value or internal friction depends on the nature of the body, large in solids, very small in viscous liquids, nil in gases.In liquids, viscosity drops rapidly as temperature rises.SPECIFICATIONS

4 cylinder in line, 16 valve 1596 cc engine with TOHC with an IAW 5NF electronic injection/ignition system.BORE -80.5 mmSTROKE -78.4 mmCAPACITY - 1596ccCYLINDER HEAD - in aluminiumCRANKCASE - in cast ironCRANKSHAFT - ductile cast iron with 8 counter-weights and 5 bearing supports with torsional damperTIMING SYSTEM - overhead camshaft, mechanical tappets, 2 valves per cylinderFUEL SYSTEM - returnless system with Marelli 5NF phased sequential injection with pintless Pico injectorsIGNITION - completely electronic inductive discharge with lost sparkEMISSION CONTROL DEVICES - three-way catalytic converter and 2 Lambda sensors (EOBD)LUBICATION - forced with geared pumpCOOLING - liquid with forced circulation via centrifugal pump and sealed circuit; radiator and supplementary expansion tankCOMPOSITION

The systems involved in the operation of the engine are:

- fuel supply system

- air supply system

- exhaust system with catalytic converter

- fuel vapour recirculation system

- lubrication system

- engine cooling system.

- The operation of these systems is optimised by an electronic control system governed by a control unit (see subassembly 1056).

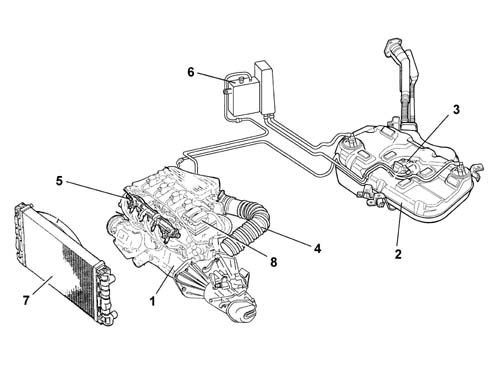

Assembly view

The engine assembly systems are illustrated in the diagram below.

Fuel supply system

It is the returnless type with an electric fuel pump submerged in the tank and enclosed in a container together with the pressure regulator, the level gauge and the filter (for further details see 1040).Air supply system

Air supply system with plastic intake anifold and large air filter casing to limit intake noise (for more details see 1048).Exhaust system

The exhaust system has a post-treatment system for the exhaust gases with a dual Lambda sensor, one upstream and one downstream of the catalytic converter fitted in the engine compartment (for more details see 1076).Emission control system

The following emission control systems are used on this model:

- exhaust emission control system with three-way catalytic converter and dual Lambda sensor;

- crankcase vapour/gas recirculation system;

- fuel evaporation control system (for further details see 1080).