3360115 - 1080E EVAPORATION CONTROL SYSTEM

SPECIFICATIONS

The evaporation control system is designed to prevent the fuel vapours, made up of the lightest parts of hydrocarbons that basically form in the tank, from being released into the atmosphere.COMPOSITION

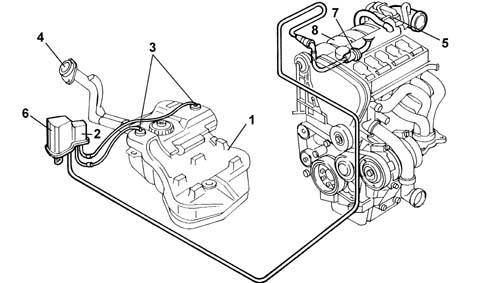

The system comprises a tank, a vapour separator, two float valves, a two-way ventilation valve inside the fuel filler cap, a carbon filter and a carbon filter scavenging solenoid valve operated by the control unit.OPERATION

The system works at high outside temperatures when the temperature of the fuel increases and as a result the tendency to evaporation also increases: in this situation the pressure inside the tank increases.In particular, even with the tank (1) full, the two float valves (3) remain open as they are located higher than the breather pipe and they consequently always alow the fuel vapours to reach the separator (2) thereby preventing fuel from escaping.The fuel vapours reach the carbon filter (6) via a calibrated port in a valve located inside the separator/vapour filter unit. This same calibrated port also allows the intake of air into the tank via the carbon filter if this is necessary after the level of the fuel has decreased.When the engine is running, the control unit (5) controls the carbon filter scavenging solenoid valve (7) which allows the intake of vapours by the engine via the intake manifold (8) and the consequent scavenging of the carbon filter.If, as a result of a malfunction in one of the components, the pressure inside the tank increases to dangerous levels, the safety valve located in the cap (4) allows the pressure to be discharged outwards. If necessary, this valve can open in the opposite direction to ventilate the tank and prevent the vacuum reaching level that are too high.

EVAPORATION CONTROL SYSTEM COMPONENTS

Float valve

These valves are used to perform the following functions:

- prevent the outflow of liquid fuel in the case of accidents where the vehicle overturns;

- allow the breathing of fuel vapours from the tank to the separator and to the active charcoal filter;

- allow tank ventilation if a vacuum builds up inside.

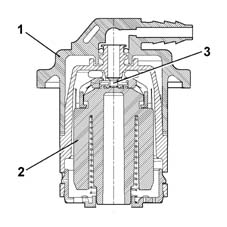

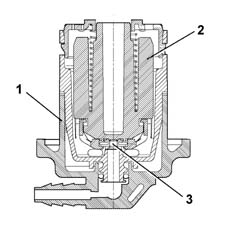

Full tank

If the tank is full, the float (2) blocks the opening (3) to prevent liquid fuel from reaching the separator.

Medium fuel level

If the fuel level in the tank decreases, the float (2) goes down, opening the port (3). This allows the fuel vapours to leave the tank and reach the separator and the active charcoal filter or, through the same circuit, to ventilate the tank when the internal pressure is lower than the outside pressure.

Seal in the case of roll over

If the vehicle rolls over, with the tank filled to any level, the float (2) acts under its own weight and the weight of the fuel on the port (3) to prevent a dangerous outflow of fuel to the vapour separator and the consequent risk of the vehicle catching fire.

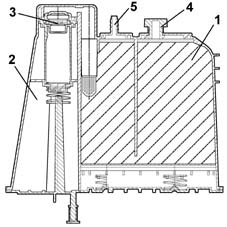

Canister

Specifications

This is fitted to the right front wheel arch and consists of an activated charcoal filter element (1) that absorbs fuel vapours from the separator (2) housed in the same assembly.The fuel vapours flow through a calibrated port (3) in the valve in the top part of the separator.A one-way valve (4) allows outside air (flushing air) to come in and flow over the charcoal granules to carry away the fuel vapours and convey them through the outlet (5) to the intake manifold when fuel vapour solenoid is open.

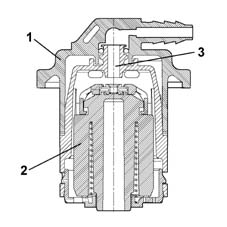

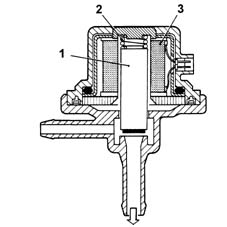

Fuel vapour solenoid valve

Specifications

It is fitted directly on the intake manifold and is operated by the injection control unit.The solenoid allows fuel vapours stored in the canister to flow through to the engine intake.If the power is off, the solenoid is closed and prevents fuel vapours from enriching the mixture excessively.Operation

The solenoid valve is operated by the control unit according to a strategy (see 1056)When the electromagnet (1) is energized it attracts the shutter (2) that overcomes the load of spring pack (3) to close the port (4) and prevent fuel vapours from passing through.

Safety and ventilation valve

Operation

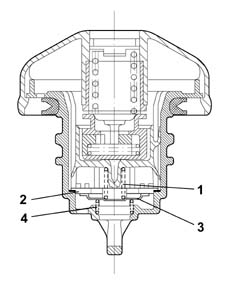

This valve is built into the fuel filler cap and performs as follows, depending on fuel pressure in the tank.

- discharges the excess pressure that is created inside the tank outwards (safety function); the pressure acts on the plate (2) and, overcoming the spring (1) loading, allows the excess vapours to be discharged to the outside.

- It allows the flow of outside air into the tank when, as a result of the fuel consumption, an excessive vacuum is created in the tank (ventilation function). In this case, when the vacuum exceeds the spring (4) loading, it move the valve (3), allowing the intake of air.