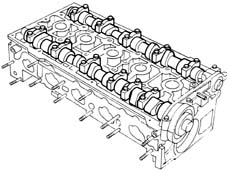

3360125 - 1036C OVERHEAD CAMSHAFTS (2) IN CYLINDER HEAD (1)

DESCRIPTION OF COMPONENTS

CAMSHAFT

Specifications

TypeThe camshafts are ductile cast iron, driven directly by a toothed belt.The intake side camshaft turns on eight mounts while the exhaust side camshaft turns on seven mounts.The camshaft oil seal function is performed at the front by oil seals.

PHASE TRANSFORMER

Specifications

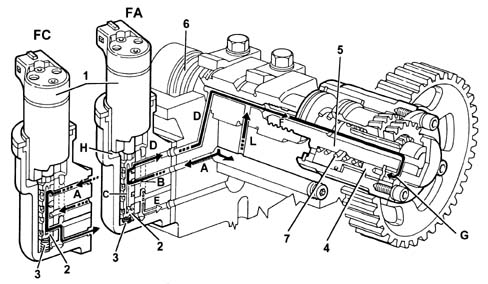

System detailsA variable valve timing system with electronic control and hydraulic acutation has been adopted for the timing side camshaft.The variable valve timing system is driven directly by the injection system and performs the function of altering intake valve timing on the basis of engine load and speed requirements.The control unit detects malfunctions in the variable valve timing system or electrical circuit and inhibits the drive.Operation

Operation in closed stage (fc)When the closed phase is required (idling and maximum power zone), the solenoid (1) is de-energized therefore the valve body (2) remains raised thrust by the opposing spring (3) preventing fluid from channel (A) from reaching the variable valve timing system.In this case, intake valve timing remains unchanged (closed).Operation in open stage (fa)When open phase is required (moderate speed at high torque). Electromagnet (1) is excited and presses valve slide (2) down.In this position, fluid from channel (A) enters chamber (B) of the piston and then flows on through a hole into channel (C) inside the piston.The fluid can leave this channel only through the upper hole (in communication with port (D) delivering fluid to the variable valve timing system). Because valve slide (2) is lowered, the lower hole is not in communication with exhaust port (E).The oil flows through channels (D) and (F) into chamber (G), which moves piston (4) sideways toward the engine. Because the piston is fitted with external helical teeth, it is forced to turn clockwise.Its rotation is transmittted via a splined curb toothed section to piston (5) which is tightened onto the threaded shank of camshaft (6) and transmits rotation to the shaft, thus altering intake valve timing by 18°.When the electromagnetic is deactivated, valve slide (2) returns to its original position to cut off the flow of pressurised fluid to piston (4) but allowing fluid to return to the exhaust under the pressure of counterspring (7).Channel (L) allows the camshaft journal to be lubricated under different operating conditions.The fluid that leaks into electromagnet chamber (H) drains out through drainage port (E).

TAPPETS

Specifications

TypeThe hydraulic tappets automatically cancel out valve play during engine operation. This offers the advantage of reducing:

- maintenance operations

- engine noise.

Operation

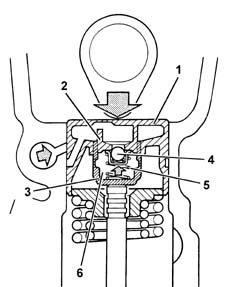

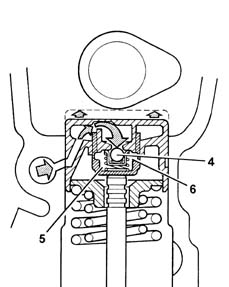

Operation in open stageWhen the camshaft cam acts on the tappet (1) and consequently on the piston (2), as a result of the closure of the ball valve (4), the oil in the chamber (6) transmits the movement of the piston (2) directly to the hose (3) and, as a result, to the valve.At this stage, due to the high pressure acting on the oil, some of the oil in the chamber (6) leaks through the tiny gap between the piston (2) and the hose (3).