198003002 - INTRODUCTION - EXHAUST GAS RECIRCULATION SYSTEM (E.G.R.)

CONSTRUCTION SPECIFICATIONS

This system makes it possible to send some (5 - 15%) of the exhaust gases to the intake in certain operating conditions.This lowers the peak temperature in the combustion chamber, restricting the formation of nitrogen oxides (NOx).The E.G.R. solenoid (1) operated by the injection control unit (2) recycles a proportion of the exhaust gases taken from the exhaust manifold (4) back into the engine intake.A heat exchanger (3) allows the partial cooling of the exhaust gases further lowering the temperature of the combustion chamber.

OPERATION

At coolant temperatures of > 20°C with the engine speed between 800 and 3000 rpm, the injection control unit operates the E.G.R. solenoid valve with a square wave signal.The variation in this signal allows the E.G.R. coil to move a shutter, thereby regulating the flow of exhaust gases from the exhaust manifold to the intake manifold; there are two results:

- less air is introduced;

- the combustion temperature is reduced (on account of the presence of inert gases) resulting in a decrease in the formation of NOx (nitrogen oxides).

DESCRIPTION OF COMPONENTS

E.G.R. SOLENOID VALVE

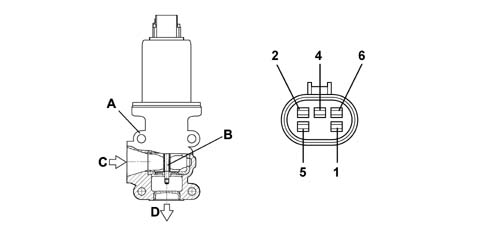

The Pierburg E.G.R. solenoid valve, fitted on the intake manifold, modulates the flow of exhaust gases to the intake according to commands from the injection control unit.This modulation is performed by the internal solenoid, which is controlled by a PWM signal from the control unit that activates the internal valve control rod.