198003012 - INTRODUCTION - HUBS AND WHEELS

TPMS SYSTEM

General specifications

The TPMS Tyre Pressure Monitoring System monitors the pressure of the tyres, sending the necessary information to the Body Computer via the B-Can.In particular, if the inflation pressure is higher or lower than it should be, the system activates an insufficient pressure signal in the instrument panel or warns that one or more of the tyres is punctured.The tyre pressure monitoring system comprises:- 4 R.F. transmitter pressure sensors located inside the tyre on the wheel rim;

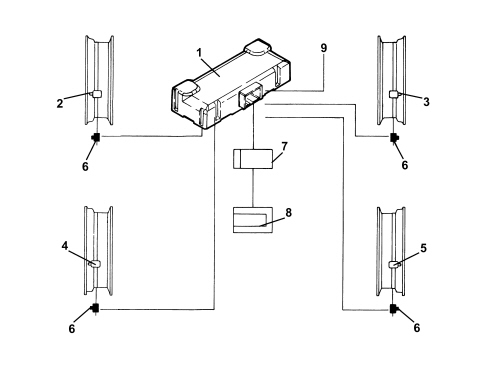

- 4 L.F. transmitters fitted on the body in the respective wheel housings;- 1 R.F. management and reception control unit fitted inside the (right) bracket supporting the rear parcel shelf;- 1 warning light/symbol signalling irregular pressure in one or more tyres, in conjunction with the display.A: - Warning light in comfort panel (medium) for all signals for the TPMS except failureA: - Symbol in matrix panel (high) for all signals for the TPMS except insufficient tyre inflation pressureB: - Symbol in matrix panel (high) signalling insufficient tyre inflation pressureC: - Warning light in comfort panel (medium) or symbol in matrix panel (high) signalling system failureThe pressure sensors continuously check that the tyre inflation pressure is correct.If a failure or a loss in pressure is detected, the sensor transmits a message via R.F. modulated in AM at a frequency of 433.92 MHz to the receiver control unit.1. Tyre pressure control unit2. Left front sensor/transmitter inside the wheel rim3. Right front sensor/transmitter inside the wheel rim4. Left rear sensor/transmitter inside the wheel rim5. Right rear sensor/transmitter inside the wheel rim6. Aerials (transmitters)7. Body Computer Node (receives the signals transmitted by the sensors from the TPMS control unit via the A-bus)8. Instrument Panel Node9. Serial k line for control unit and TPMS fault diagnosisTransmission of tyre status via a-bus/b-can

The tyre pressure control unit (CPP) acquires information, via radiofrequency, from the sensors, relating to the status of all four tyres and transmits it via the A-Bus line.The control unit transmits the following information:- CPP control unit programming/characterization status;- possible entire system fault;- tyre position;- tyre inflation pressure status.Tpms operating principle

At the key-on the control unit sends the Body Computer a confirmation signal indicating that it is working properly via the BUS serial line.The aerials (transmitters) send a 125 kHz signal to the sensors on the wheels so that initialization takes place. The sensors, in turn, measure the pressure and send an RF signal for the tyre pressure and temperature status; the receiver receives this transmission from the sensors inside the tyres, immediately forwarding the information on the serial B-Can (via a Body Computer A-Bus gateway).When the value of the pressure goes below or above the pre-set levels, the control unit signals the alarm status directly to the instrument panel, via the B-Can, switching on the special warning light and visual and acoustic warning messages.Within 2.5 seconds of the key-on, the TPMS control unit will start its periodic transmission of messages; if this does not take place within this period, the control panel will signal the TPMS failure condition. The same will take place if the transmission of the TPMS_Status message is absent for more than 2.5 seconds at operating temperature (after the switch due to the key-on).- acoustic alarms (only in the event of a punctured tyre).Intervention levels

There are two intervention levels which are stored in the receiver memory.The first (known as the CHECK level) is designed to signal if the pressure of one or more of the tyres is slightly below or slightly above the optimum level in which case the driver should check it and restore the correct value:The intevention levels for the first CHECK level are as follows:- drop in pressure of 0.3 bar in relation to the nominal value (with tyre hot)- drop in pressure of 0.45 bar in relation to the nominal value (with tyre cold)- tyre pressure higher than 3.4 bar.The second level (known as the WARNING level), on the other hand, is established to signal a loss in pressure due to the fact that one or more of the tyres is presumed to have a puncture: WARNING = drop in pressure of 0.5 bar in relation to the nominal value.Display in instrument panel

The instrument panel acquires these signals and manages the readings as described below.When the pressure value of one or more of the tyres exceeds the first CHECK level (nominal pressure - 0.3 bar when hot or - 0.45 when cold) (pressure above 3.4 bar), the TPMS warning light/symbol comes on in the instrument panel and an alphanumerical message appears in the display e.g. "Check tyre pressure", right rear or left rear. When the signalling cycle is over, only the warning light remains activated in the panel until the correct pressure is restored.The warning cycle is repeated after 10 minutes (once).The CHECK level features a message indicating the tyre involved.Warning light/symbol associated with the message: "Check tyre pressure"If the control panel receives a signal that the pressure is below the WARNING level (nominal pressure - 0.5 bar), the TPMS warning light/symbol comes on and the message appears in the alphanumerical display "Insufficient tyre inflation pressure - right front - do not continue" accompanied by a buzzer dependent on the "priority 0" fault logic (See 5560).When the signalling cycle is over, only the warning light remains activated in the panel until the correct pressure is restored.A: - Warning light in comfort control panel (medium) together with the message: "Insufficient tyre inflation pressure, left front: do not continue"B: - Symbol in matrix control panel (high) together with the message: "Insufficient tyre inflation pressure, left front: do not continue"If there is a fault in the tyre pressure control unit, the "general failure" warning light comes on and the corresponding alphanumerical display shows "Tyre pressure monitoring system not available".A: - Warning light in comfort control panel (medium) together with the message: "Tyre pressure monitoring not available"B: - TPMS symbol in matrix control panel (high) together with the message: "Tyre pressure monitoring not available"This takes place in the following cases:- fault in the control unit wiring and circuit;- no signal received from one or more sensors (sensor battery run down, faulty, broken)- TPMS control unit faulty- one or more aerials (initiators) faulty- use of one or more wheels without sensors (e.g. with snow tyres).The display takes place about 12 minutes after the fault is detected.The display occurs when the CAN message is received if and only if the vehicle speed is above 20 km/h for several minutes.System not programmed: if the tyre pressure control unit has not been programmed, the TPMS warning light/symbol will come on in accordance with the following modes.A: - Warning light flashing in comfort panel (medium)B: - Symbol on in matrix panel (high)System disabled: the system can be disabled on the customer''s request if the vehicle equipped with a TPMS system has tyres without pressure sensors (e.g. winter tyres). In this case the control panel will not provide a TPMS signal. When the customer fits new wheels with sensors, they should go to a Fiat Dealership, who will restore the operation of the system.To disable the system, give the appropriate command to the control unit using the Examiner (obviously, at the key-on), then, in order to ensure that the operation is successful, wait at least 10 seconds before removing the key (key-off, a manoeuvre required for the command to be received. The duration of the key-off must also be at least 10 seconds), otherwise the procedure will not be successful and the control unit will not be disabled.Tyre pressure control unit (cpp)

The CPP is connected to the rear wiring by means of a braid.The receiver electronics are housed in a plastic casing that is not screened against radio frequencies.The control unit is not designed so it can be fitted in only one possible position, so it must be fitted so that the container is facing the vehicle exterior (right-hand side) so that it is easily accessible by sliding your hand inside the shelf.The CPP is an electronic component which, connected to the A-Bus serial line, manages the tyre pressure control function; the fault diagnosis is managed using the K-Line serial line.The system is also capable of diagnosing the operation of each sensor and the entire system. It detects:- faults in the control unit wiring and circuit;- no signal received from one or more sensors;- faults in the actual control unit;- one or more aerials (initiators) faulty.If there is a break in the control unit power supply, the new sensor ID codes should not be stored in the control unit memory; the IDs and the position of the sensors, as well as the error codes (fault diagnosis) remain stored in the control unit EEPROM.CONTROL UNIT PIN OUT1. Power supply +302. L.F. transmitter power supply3. Left rear L.F. transmitter signal4. Left front L.F. transmitter signal5. Right front L.F. transmitter signal6. Right rear L.F. transmitter signal7. N.C.8. Can_L_Bus9. Can_H_Bus10. Earth11. N.C.12. L.F. transmitter earth13. L.F. transmitter earth14. L.F. transmitter earth15. L.F. transmitter earth16. Supply controlled by ignition (+15)17. N.C.18. N.C.CONTROL UNIT REPLACEMENTIf the CPP is being replaced, the following operations must be carried out:- programming of the nominal pressure values for the front and rear axles with medium and heavy loads (or at low and high speed), in accordance with the instructions in the Owner''s Handbook for the vehicle depending on the version;- set the programmed control unit bit “TyrePressureSysProgrammedSts=0”;- set the enabled control unit bit “TPMSActivitySts=0”;- carry out a key-off/key-on manoevure;- make a journey with the vehicle at a speed above 20 km/h for several minutes to allow the self-learning of the sensor IDs.Tyre inflation pressure sensors

The sensors are located inside the wheel rims in place of the normal tyre inflation valve.The sensors have the function of checking the value of the pressure and tempearture of each of the tyres and transmitting the information via a radiofrequency signal (433.92 MHz) to the control unit/receiver.The sensors measure the pressure and the temperature inside the tyre by means of dedicated pressure and temperature sensors which are combined with electronics for acquiring and processing the signals and are equipped with a section designed for transmitting these signals at a radiofrequency of 433.92 MHz.The sensor assembly is supplied by a 3.6 V lithium battery that lasts 10 years in normal usage conditions.When the battery for one or more sensors is run down, DTC control unit errors are set in the memory detailing poor battery charge conditions.The failure is not necessarily displayed in the control panel. The fault is set only when the level of battery charge is no longer sufficient to guarantee the transmission of the signal. The DTC associated with fault signalling will therefore be due to the lack of radio frequency signal transmission from one or more sensors (the cause of which, in this case, is insufficient battery charge). If, in the error memory relating to the sensor that generated the fault, there is also a low battery charge DTC for that sensor, it means that it has exhausted its battery and should be replaced.There is a certain operating margin for the sensors from when the DTC in question is set.The failure is only set when the transmission is definitively adversely affected (for example, as a result of the battery being EXTREMELY run down).If the sensor for a run down battery is replaced, it is advisable to check the others (by reading the DTCs) because they will probably be in a similar condition to the one which is run down.COMPOSITION1. Nut2. Valve cover3. Valve4. Sensor5. Valve opening6. Square section bolt1. Nut2. Valve cover3. Valve4. Sensor5. Square section boltProgramming the sensor ids in the control unit

In the event of:- replacing a sensor;- changing the position of a wheel (e.g. swapping front - rear): the procedure described must be carried out in order to memorize the sensor ID code in the control unit so that the control unit can recognize them as belonging to the system and consequently manage the radio frequency signals coming from them. This procedure should be carried out using the diagnostic equipment (Examiner) or through the self-learning procedure, which consists of driving the vehicle at more than 20 km/h for several minutes to allow the self-learning of the sensor IDs.By using this routine, this identification code can then be written inside the control unit memory. In this way the control unit recognizes transmissions coming from the new sensor and manages them correctly.Aerial (transmitter)

The aerials are fitted on the body in the respective wheel housings compartments. Their task is to initialize the pressure sensors fitted on the wheels. At the key-on they transmit a 125 kHz signal to the sensors. These receive the signals and, in turn, transmit them to the TPMS control unit modulated in AM at a frequency of 433.82 MHz.1. Earth2. Signal3. Fuel system