312001181 - MANUAL GEARBOX AND DIFFERENTIAL - INTRODUCTION

CONSTRUCTION SPECIFICATIONS

The C514 gearbox fitted on the vehicle is a gearbox that has been developed to improve manoeuvrability and reliability and is fitted in conjunction with the 1.2 8v and 1.3 Multijet and 1.4 16V 5 speed versions.This version is the most powerful gearbox in terms of torque transmitted (15 kgm). The use of noble materials for the gears, the use of a powerful differential with oversize conical gears and the connection between the casing and ring gear using bolts ensures maximum reliability.Its main features are:

- excellent manoeuvrability of the gear control

- quiet operation

- reduced weight.

The structure of the C514 5 speed gearbox is composed of:

- a gearbox casing containing and supporting the main and layshafts, the gear engagement forks and rods and the gear selector/engagement device;

- the rear cover which contains the 5th speed gear and the bearing retaining plate for the main and layshafts;

- a casing joining the gearbox to the engine, containing the clutch, the thrust bearing and the control linkage.

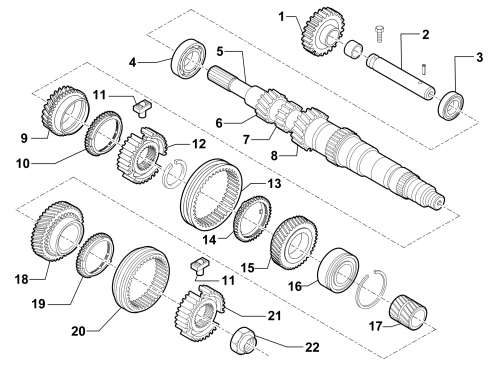

Main shaft

The main shaft consists of:

- gears for 1st and 2nd speeds and reverse formed directly on the shaft;

- gears for 3rd, 4th and 5th speeds fitted on the shaft.

Layshaft

The layshaft consists of:

- 1st, 2nd, 3rd, 4th and 5th speed gears fitted on the shaft.

The layshaft mounting consists of:

- a front roller bearing

- a rear ball bearing.

Gears

The gears are the following type:

- helical toothed for the forward gears

- straight toothed for reverse gear.

The gears and drive chain components inside the gearbox are lubricated dynamically, by means of the oil flowing along channels and through ports in the casings, the 3rd/4th speed rod and the main shaft. This allows:

- improved torque transmission and greater efficiency against the effects of wear

- manoeuvrability even at low temperatures thanks to the use of synthetic multigrade oil.

Synchronisers

Synchromesh on all the forward and reverse gears is brass baulk ring type (Borg-Warner type) and is arranged for 1st and 2nd speeds on the layshaft and for 3rd, 4th and 5th speeds on the main shaft and for reverse on the idler axis.This solution reduces gearbox noise when parked in neutral because 3 of the 5 pairs of gears are not driven.The engagement and synchronization loads are also reduced as a result of the corresponding reduction in the inert rotating masses downstream of the crankshaft.The synchronizer on 1st and 2nd speeds (the gears that are most used by the customer and thus subject to the most stress) is a double cone requiring far less engagement force than for a conventional single cone synchronizer of the same size (- 40%).A new pre-synchronizer system comprising thrust bearing blocks is used on all the gears for smoother, more positive gear shifts: in 1st and 2nd speeds the sliding gears are supported by a needle cage. The geometry of the reverse gear teeth has been improved to guarantee excellent manoeuvrability and rapid and precise engagement.Differential

The differential unit is located in the rear part of the gearbox casing.It comprises:

- a reduction cylinder pair

- a differential housing in a single piece which incorporates the planet and satellite gears.