312000287 - INTRODUCTION - TIMING SYSTEM

SPECIFICATIONS

Two ductile cast iron, overhead camshafts in a camshaft housing; they are operated by a belt and gears.COMPOSITION

The shafts incorporate appropriately positioned and profiled cams; one for each valve to be operated.The front of the exhaust shaft is designed for installation of a toothed pulley, which transmits drive from the crankshaft via an appropriately tensioned toothed belt. (see "Procedures for repairs")A pair of gears, fitted behind the shafts, allows the transfer of drive from the exhaust shaft to the inlet shaft.

HYDRAULIC TAPPETS

The hydraulic tappets used on this engine type automatically take up valve clearance during engine service. This offers the advantage of reducing:

- maintenance operations

- engine noise.

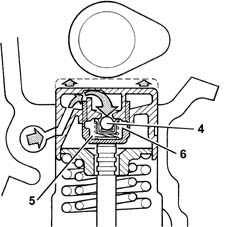

Operation in open stage

When the camshaft cam acts on cup (1) and thus piston (2), the oil trapped in chamber (6) due to the closure of ball valve (4) transmits the movement of piston (2) directly to hose (3) and consequently to the valve. At this stage, due to the high pressure acting on the oil, some of the oil in chamber (6) leaks through the tiny gap between piston (2) and hose (3).

Operation in closed stage

During valve closure, as long as the tappet pressed by the action of spring (5) follows the cam outline, a vacuum builds up inside chamber (6), bringing about opening of ball valve (4) to allow oil to enter. The oil taken into chamber (6) replaces the oil that leaked out during valve opening.

Timing drive belt route

The following figure shows the route of the timing drive belt.