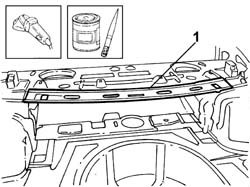

501103 - 7210B25 REARSCREEN BASE CROSSMEMBER

| The vehicle should be in the following condition before the operation: rearscreen removed, boot lid removed. |

| When the operation is completed, refit the elements removed previously. |

| The vehicle should be in the following condition before the operation: rearscreen removed, boot lid removed. |

| When the operation is completed, refit the elements removed previously. |