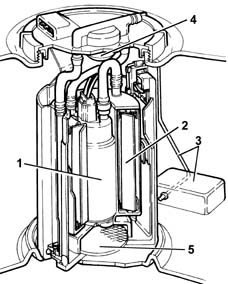

2888225 - 1040A fuel tank and components

IMMERSED PUMP ASSEMBLY COMPLETE WITH FUEL GAUGE

It is mainly composed of:

- electric fuel pump (1)

- fuel filter (2)

- float-type fuel gauge sender unit (3)

- diaphragm pressure regulator (4)

- mesh pre-filter (5).

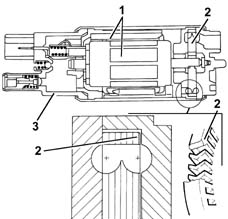

Electric fuel pump

The fuel pump comprises a permanent-magnet electric motor (1) which controls the pump impeller (2), and a terminal-carrier cover (3), which contains the electrical and hydraulic connections.The pump stage is of the single type with peripheral flow, with high performance under low voltage and temperature conditions.Its advantages compared with pumps operating in accordance with the positive-displacement principle are:

- light weight

- small size.

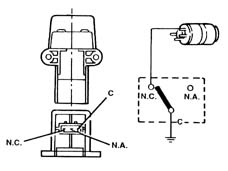

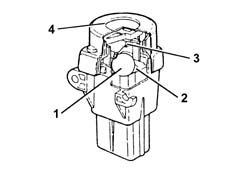

INERTIA SWITCH

In the event of a crash, the inertia switch, mounted under the driver's seat, breaks the fuel pump's connection to earth and consequently the supply to the fuel injection system.

| After a crash, even if minor, if a smell of combustion or fuel leaks are perceived, do not reset the switch, but seek the cause of the fault and eliminate it, in order to avoid risks of fire. Otherwise, if there are no leaks and the vehicle can be restarted, press the button to reactivate the pump. |